On January 30th, we hosted a webinar together with viriciti. You access the webinar replay here (link). The webinar was co-hosted by Hugo Bitouze, Europe Operations at Viriciti and Gil Peleg, VP Operations at Optibus.

Hugo Bitouze opened the webinar presenting key figures about the Electric Bus market

- 450 billion bus journeys worldwide per year, representing 83% of public transport

- 79% of buses in Europe today run on diesel

He mentioned that by 2025 one third of all European buses are expected to be electric.

Most major bus manufacturers are joining the electric market, this is linked with political efforts (the European JIVE/JIVE2 funding program for fuel cell electric buses), as well as legislation that requires a minimum of electric buses in a fleet.

To integrate EV buses there are three main areas of expertise:

- Buses

- Charging infrastructure

- Planning and scheduling

These, in turn, give rise to new responsibilities for everybody involved:

The operations team: is required to ensure reliable and smooth service

The maintenance team: is responsible for delivering reliable and fault-free buses and maintain EV and charging infrastructure. They need to understand these new elements (batteries and charging infrastructure) and how to optimize them.

The planning team: needs to plan in accordance with the energy levels of EVs and use data to predict the energy consumption of the buses and build schedules accordingly.

The first challenge is “Range Anxiety” or how far a bus can go without recharging.

Factors influencing electric vehicle utilization & range

That need to be taken into account:

Weather: Buses consume more energy in cold surroundings

Driving style: the driving style – from the frequency of pressing the accelerator to the number of passengers, road types, urban/ countryside – all affect the vehicle energy levels. Which is why the operations team needs visibility regarding these factors and should also make the relevant decisions, not leaving these decisions to the drivers.

Electric buses get energy back from regenerative breaking, and therefore it is important to monitor and train the drivers to optimize the energy when they drive the bus. Good driving habits can reduce energy consumption by 5 to 20%.

The maintenance team has to deal with the new technology. A battery is a combination of packs full of cells and it degrades over time. As the battery discharges these packs are emptying themselves, yet they do so at different rates, so some of the packs are emptied quicker than others, and then the battery automatically shuts down. The maintenance team should be able to locate these broken cells and replace them. Replacing a whole pack will take longer and be and more expensive.

Charging infrastructure: there are 2 types of chargers: in depot – all buses at night and on route charges/ opportunity charges, when your buses charge quickly, in a few minutes before running again.

Real time information on the charging stations is essential, if buses run out of battery or chargers do not work the entire schedule is affected.

Data from the charging stations varies from charger’s availability, the available power, to real time alerts. Since 80% of problems that linked to the charging infrastructure can be solved remotely, a smart charging tool that allows to reset the charger remotely can solve many problems.

As the electric fleet grows the smart charging tool becomes even more crucial as more parameters need to be taken into account: energy prices, grid connection, grid limits etc. These make it even harder to have a smooth and reliable charging process. A smart charging module can have 40% lower peak load which helps avoid grid connection costs, and saves a lot of the battery health.

Gil Peleg of Optibus spoke of how the Optibus platform uses Viriciti’s insights about what each vehicle can do, and how the schedule of an electrified fleet can be optimized.

The challenges when scheduling for EVs, are an inability to plan and schedule properly, planning charging stops, a possible increase in Peak Vehicle Requirements as a result of charging, and charging that may interfere with driver breaks.

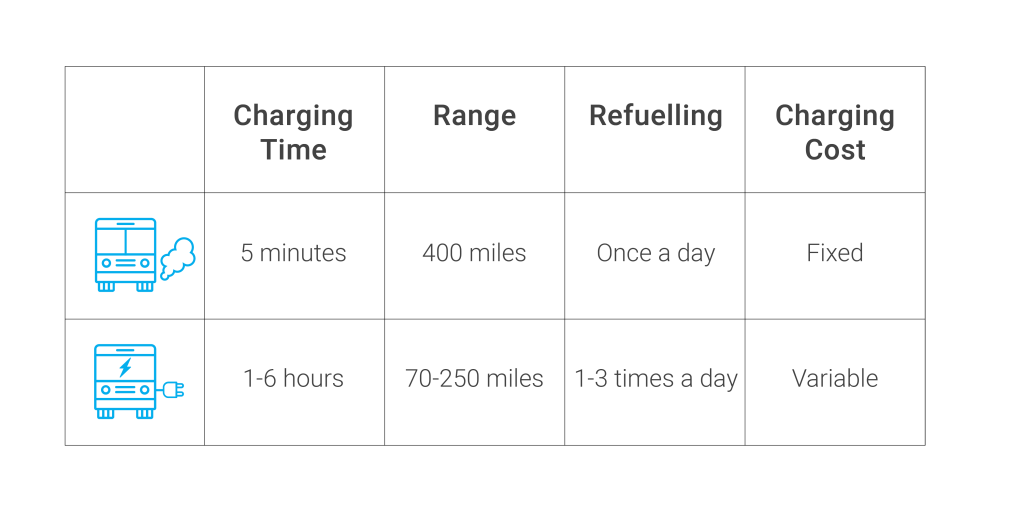

Four key components to think about when comparing diesel versus electric:

Other decisions have to do with whether you charge your battery completely to 100%, or partially. With diesel you refuel once a day with electrical you need to recharge on an ongoing basis. Diesel prices change every day but not dramatically on the other hand electricity prices change dramatically even within the day, so charging times matter too.

One common practice is to use the EV only at peak times, when the Peak Vehicle requirement is at its highest, and charging the buses for the rest of the time. However this is not the optimal solution and a lot of value or electric miles are left on the table.

Hence the first step to solving this problem is coming up with a scheduling strategy.

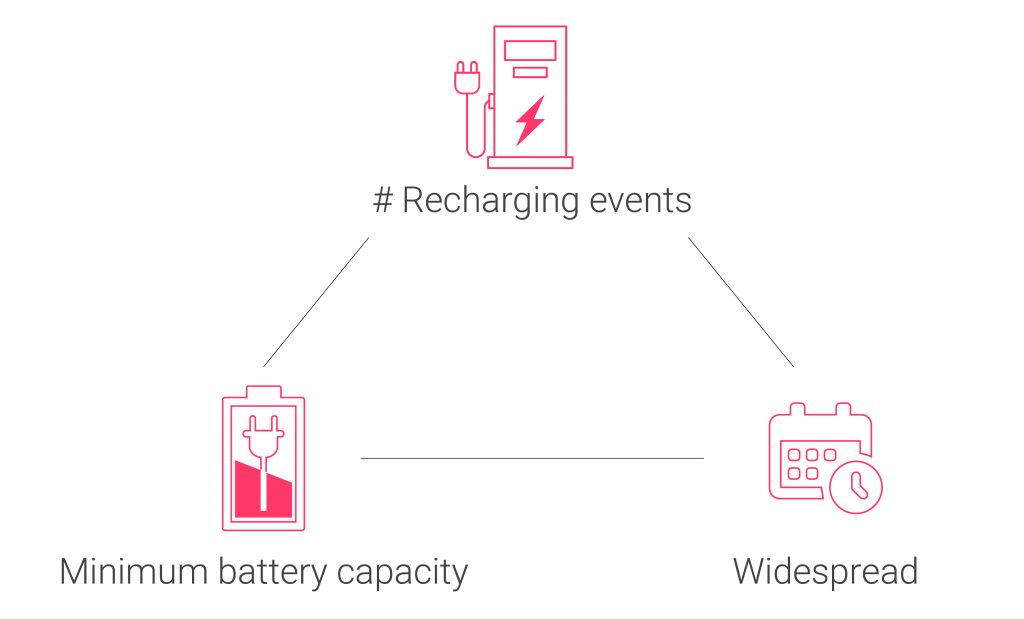

In order to develop this strategy we need to understand a few things: first what is the minimum battery capacity needed, taking into account whether you are running long or short routes and where charging stations are located.

Widespread is a technical term that speaks to the length of time you take between trips when a bus comes into the depot or the garage, how much time will pass till the next trip. It’s an important number for diesel but it is key for electrical since that time dictates the charging time for the vehicle.

The third factor is how many recharging events you wish to have. It depends on who is charging the vehicles – the drivers or the engineers. It also dictates whether you charge one time to 100% or use a few short bursts of energy to keep the vehicle with just enough energy to complete the operation.

In order to addresses all this, we introduced EV-related rules and preferences into the EV module of the Optibus platform.

For batteries we need to indicate: battery type, battery capacity, minimum capacity, discharge rate (you can get the data from the OEM or from a vendor such as a Viriciti that has real-time data).

For chargers we need to indicate: the charger’s profile, battery types supported, minimum charging time. We realize it takes time to park and prepare the vehicle for charging, charging rate, charger’s location and capacity (how many vehicles can be charged at once).

Regarding electricity costs, they change during the day and we can add different time tranches with different prices (high/ low) and the system knows how to take it into account while building the optimal schedule.

Finally EV operates as part of a holistic schedule, and it cannot overrun existing requirements and constraints for vehicles and drivers, and the standard operational routine for a transit agency or operator.

The webinar then compared two different charging strategies: one with short charges and the other with a full charge. In this example, the short charge strategy was more complex to operate but required less vehicles. This, however, changes on a case by case basis and needs to be modeled beforehand.