Where would we be without bus drivers?

Your bus routes might be perfect and your schedule meticulous, but a lack of drivers can leave cities, transportation companies and passengers stranded. Driver shortage caused transportation delays across the U.S. last year and is projected to intensify in the UK as driver job applications from Europe dry up ahead of Brexit.

So what should cities and transportation providers do about it?

Alongside pay, one of the key elements of maintaining the driver workforce and attracting new drivers is good working conditions.

This includes not just the essential basics – complying with the break and rest regulations mandated by laws and labor agreements – but also doing a good job of honoring individual drivers’ work preferences as much as possible while simultaneously building an effective and efficient roster for all drivers.

As bus operators in the UK and Europe already know, using rotating rosters (or rotas) – in which drivers rotate through each roster line, so that all drivers ultimately end up having the same workweeks, just at different times – is an effective way to build an equitable roster.

But what transportation providers and cities may not realize is that in order to get the most out of rostering, enabling them to make life more fair for drivers and easier for schedulers, a little something extra is needed. That secret sauce is called roster optimization.

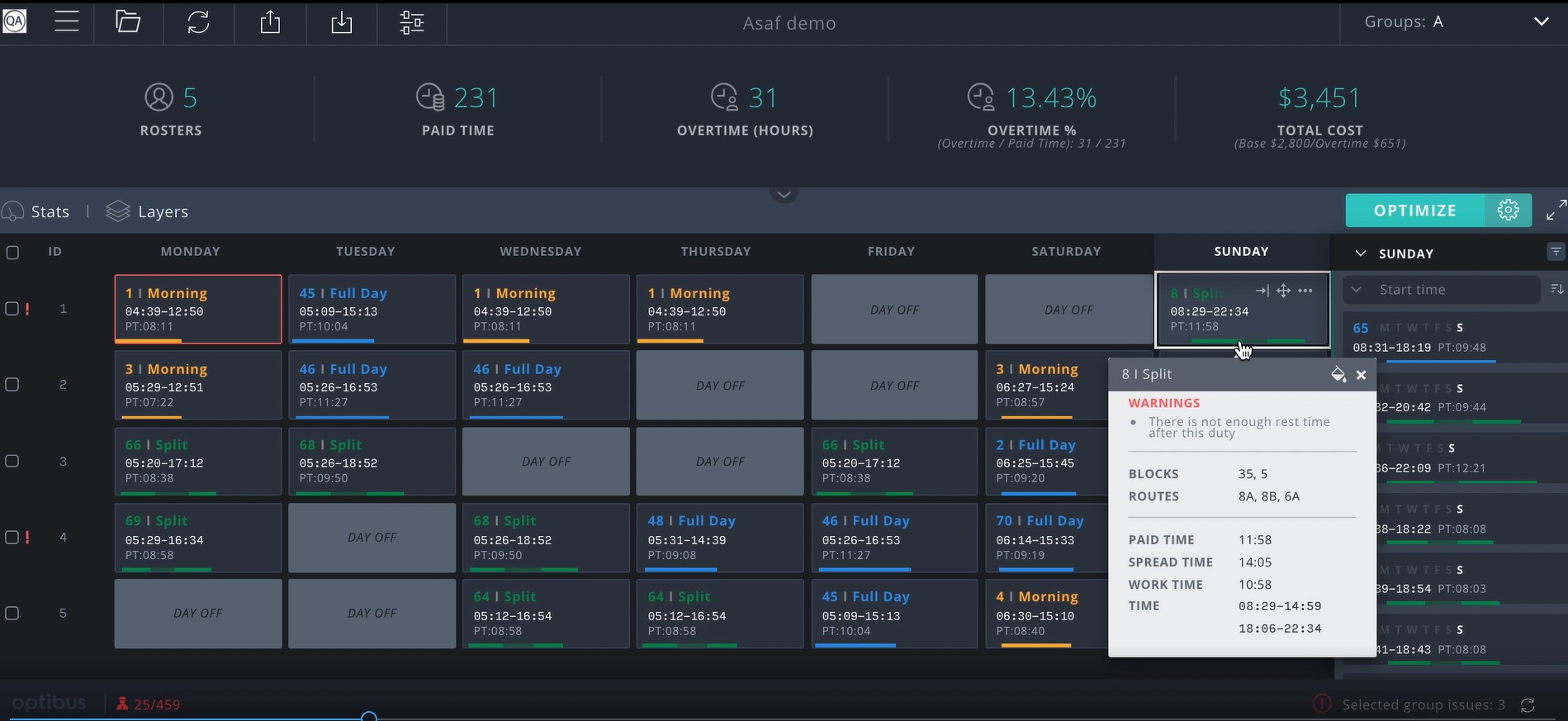

A sample roster on the Optibus platform. Roster lines 1 and 4 have warning signs to let schedulers know if the roster doesn’t comply with their rest and break rules.

In a regular roster, as above, the platform checks whether there’s enough rest time between the last day of the roster line and the first day of the same line, since the same driver performs the same roster line every workweek. In a rotating roster, the platform checks the rest time between the last day of the current roster line and the first day of the next roster line, since all the drivers in the group rotate through each roster line.

Benefits of using rotating rosters

Before addressing what rotating roster optimization is and how it can help both drivers and schedulers, let’s take a moment to review the benefits of rotating drivers through the same roster lines.

These benefits include equitable duty allocation for drivers and the increased ease of matching multiple drivers to a given duty, which can benefit schedulers and dispatchers as well as drivers.

Let’s look at a simplified rotating roster with only three drivers: Tim, Jane and Bob.

Tim is assigned roster line 1, Jane is assigned roster line 2 and Bob is assigned roster line 3. Since each driver moves on to the next roster line after each is completed, the next week Tim would get roster line 2, Jane would get roster line 3 and Bob would get roster line 1. This can continue indefinitely.

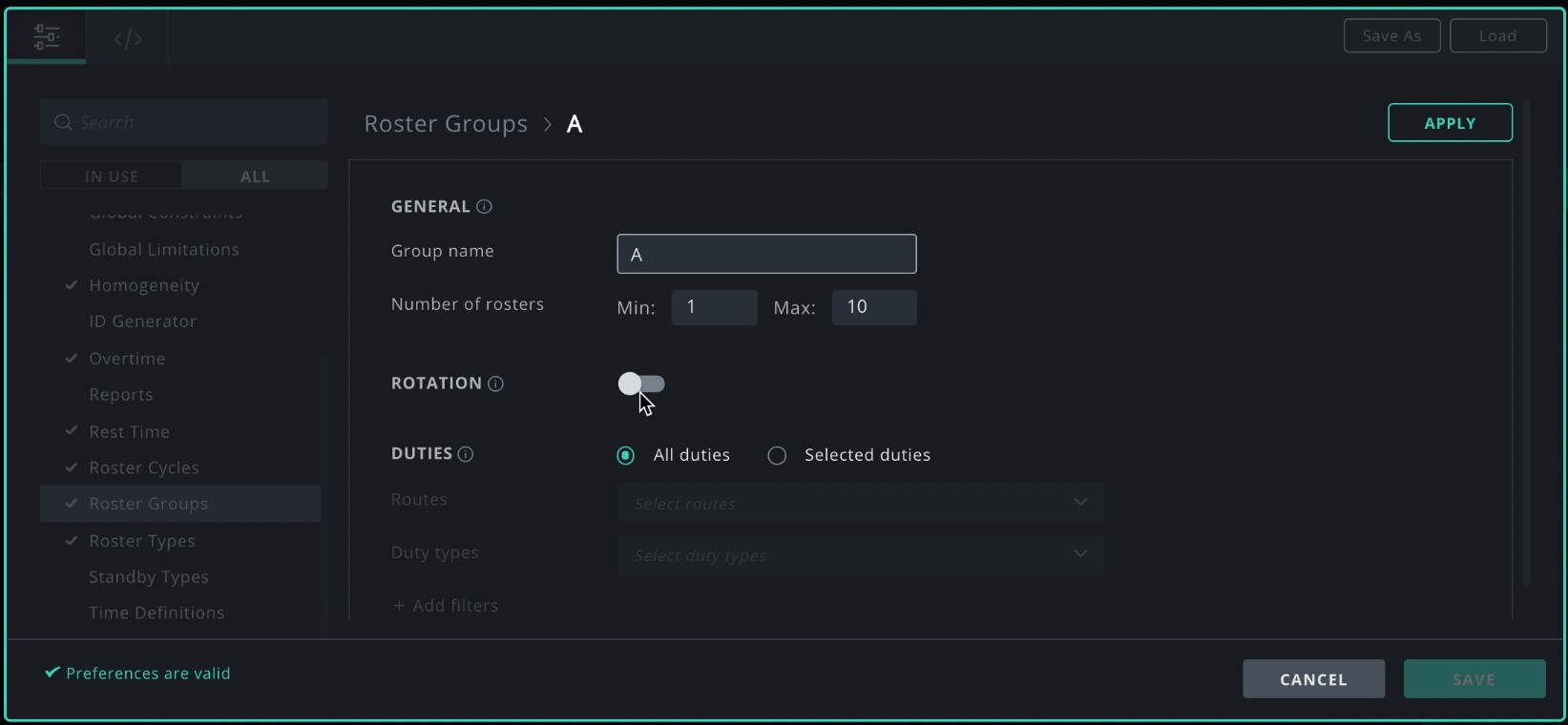

Creating a rotating roster on the Optibus platform: Just turn on the Rotation button. Schedulers can decide to have rotating rosters for some groups of drivers and not others.

More equitable

Rotating rosters are more equitable for drivers because all drivers allocated to the same roster group rotate through each of the roster lines for that group.

Let’s say roster line 1 is in high demand – maybe it has no split shifts, or doesn’t start too late or end too early. This means all drivers in the group will get preferred roster lines at least some of the time. While assigning it to a single driver may be good for that specific driver, assigning it to all drivers on the roster, on a rotating basis, allows all drivers to benefit sometimes, by being assigned that roster line at set intervals.

The roster lines for a given set of drivers can be similar (for instance, they can have roughly the same start time), or drivers can cycle through alternating roster lines (for instance, an early week followed by a late week). Either way, drivers with rotating rosters benefit from knowing what their week will look like far in advance, allowing them to make personal plans around their working hours.

In addition, some drivers say they prefer taking on the diversity of tasks that may be available with a rotating roster because it makes their work more interesting.

Easier to maintain

On top of being more fair to drivers, rotating rosters are also easier to maintain, because drivers can readily switch weeks or cover for each other if someone is sick or running late, since everyone on the same roster is familiar with the same routes.

Having other drivers able to cover or switch makes it easier for dispatchers as well as drivers, while being able to slot in any one of a group of drivers on the roster makes rotating rosters easy on schedulers. With rotating rosters, drivers can still get “good” roster lines, yet schedulers don’t have to tailor them to specific drivers.

How does roster optimization help?

Rotating rosters can benefit schedulers, dispatchers and drivers whether the rosters are built manually or with the help of optimization.

Those built without optimization – whether created by schedulers or based on driver picks in cafeteria-style rostering – not only take longer to schedule, but can also add unnecessary labor costs such as overtime and run a high risk of failing to comply with labor laws and agreements.

Reduced labor costs

Labor costs can rise unnecessarily when roster lines do not correspond closely with trip times.

With cafeteria-style rostering, for instance, veteran drivers may pick longer runs with more overtime than needed to cover all trips. This also contributes to less equitable rostering, with the more junior drivers left with less desirable roster lines.

Optimization, by contrast, results in driver roster lines that comply with labor laws and agreements – and can express driver preferences as well – while simultaneously minimizing unnecessary overtime and guarantee time.

Compliance with labor rules

For a closer look at how roster optimization helps schedulers ensure that break rules and other labor restrictions are met, let’s take a roster with the following requirements:

- At least nine hours of rest time between days

- At least two consecutive days off per roster line

When a non-rotating roster is optimized, each of these rules is validated within a given roster line, since drivers perform the same duties each week. When rotating rosters are optimized, the validations take the adjacent roster line into account as well, since drivers switch duties from one roster line to the next.

In some cases, duties that are valid when looking at one roster line at a time are invalid when evaluated in the context of a rotating roster. For instance, you can see in the example below that for a rotating roster whose roster line starts Monday and ends Sunday, a split shift that ends late at night on the last day of roster line 1 (Sunday) will receive a validation error because there’s not enough rest time before the first shift of roster line 2 (Monday).

In other cases, some duties may be valid for a rotating roster that would not be valid when looking at one roster line at a time.

In the example above, roster line 4 does not have two consecutive days off. While this is flagged as a violation of the labor requirements when looking at a standard roster, in the rotating roster it is no longer a violation because the last day of roster line 4 (Sunday) and the first day of roster line 5 (Monday) are both days off, giving the driver the necessary two consecutive days off.

We’ve seen that rotating rosters are more equitable for drivers and easier for schedulers and dispatchers to maintain, and that optimization can reduce labor costs and make it simple to comply with labor rules. Those who currently use rotating rosters may already recognize the value of enabling drivers to rotate through set roster lines, but it’s important for transportation providers and cities to also realize that optimization is what allows schedulers, dispatchers and drivers to get the most out of rostering.

Related articles:

How Rosters Make A Huge Operational Difference

MV Transportation: Improving Efficiencies

Relief Vehicle Scheduling: The Forgotten Optimization Dimension